Modular technology

Endless and fashionable

The technology of Revonia’s vaults is unique. We have studied old vaulted cellars, which have allowed us to learn from past building masters. We have incorporated their knowledge into building our vaults, developed it further, and brought it together with contemporary construction techniques and materials.

Drawings and assembly examples

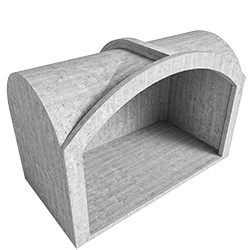

Hexagonal chamber

Domed vault | 4,5 m2

The hexagonal module can be used both individually and attached to other modules. View assembly examples

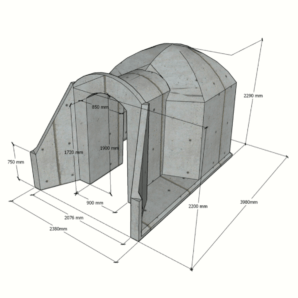

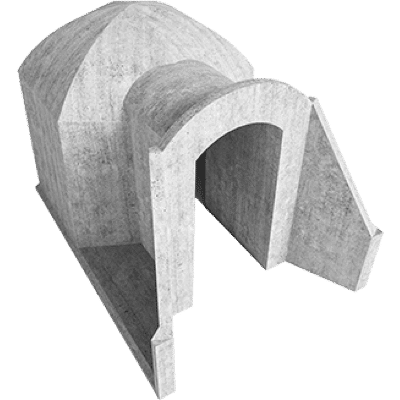

Chamber with an entryway

Arched vault | 11,7 m2

The entryway can be located along the longer or shorter wall of the chamber. View assembly examples

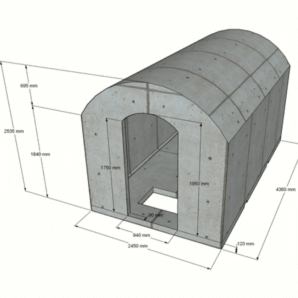

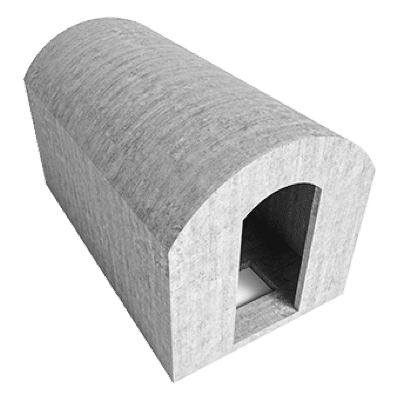

Additional chamber

Arched vault | 9,7 m2

The additional chamber allows for expansion. View assembly examples

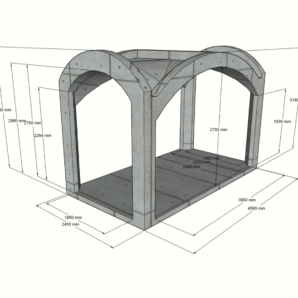

Cross vault module

Cross vault | 10,2 m2

Cross vault modules can be attached to one another along both the longer and shorter side. Both the longer and shorter cross vaulted modules can be left open or have windows and doors installed. View assembly examples

Just as spacious as you need

Our arched vaulted units are made of three different modules. The smallest with a hexagonal floor surface of 4.5 m2. The entryway and the additional chamber module with rectangular floor surface to create an even larger 11.7 m2 space. The ceiling height of the modules is 2.5 m.

You can choose from these modules to construct a space just as big as you need. The modular rectangular units can be attached to each other, along both the longer and shorter sides, and also combined with the hexagonal module.

Our cross-vaulted units are made of base modules with 10.2 m2 of floor surface and 2.7 m2 of ceiling height. They can be closed up or left open on all sides in order to attach the modules to one another, to install windows and doors to the building, or leave it open altogether. It is possible to connect arched vault modules and cross vault modules.

The possibilities are endless – you can construct a nice sauna, a distinguished wine cellar, or a party and leisure room with a great atmosphere and just the right size, character, and design.

See some examples we have already built to get an even better idea.

Advantages of our technology

The speed and comfort of installing

- It usually takes us only one day to install a new cellar, sauna, house or vault for other purposes.

- On-site, we install the modules in place and, if possible, connect the electrical wiring. Detailed videos of the process here.

- A separate foundation is not needed. The slab foundation is already integrated into the module. All that is required for installation is a simple gravel pad that is level. The corresponding instructions for this are included with the order.

- The only thing left to do after installation is the covering of the modules with soil and creating the desired look. You can also use the soil that was excavated when making the rubble pad for covering. We recommend finding a local company for the excavation works, because this way the cost will be cheaper and you will also support local producers.

- Installation is possible both in summer and winter, on both dry and slightly wetter soil. If you doubt the suitability – write to us. In the case of more complex projects, we can also come for a visit.

- We also make sure that the beautiful backyard does not suffer due to the installation. When transporting over the lawn, we use hard alloy mats that save landscaping.

- We offer turnkey solutions as well as the option where you can purchase only a concrete body and make the desired finish on it yourself.

Indoor climate and susability

- Vaulted ceilings ensure excellent air circulation.

- We finish the walls and ceilings with lime plaster, which has a sterilizing effect and prevents the formation of mold and fungi.

- The doors are made of solid wood, with swallowtail support beams. The hinges, handles, and latches are forged out of metal.

- The indoor climate and temperature can be regulated with air outlet and intake panels.

- Different windows can be installed on the building according to the wishes. In the case of residential buildings, the most popular options are floor-to-ceiling windows that bring a lot of space and light, as well as skylights.

Energy efficient and eco-friendly

- The modules are made of reinforced reinforced concrete with an expected lifespan of ~100 years.

- On buildings insulated with PUR foam and soil, we achieve near-zero energy efficiency.

- By covering with soil, there is no need to maintain the exterior walls, roof, foundation, insulation, and many other things in the future.

- The building has an underground, or geothermal, ventilation system, and to ensure constant temperature, humidity and air circulation, the building uses the passive energy of the ground.

We use natural materials in the interior decoration.

Revonia Green+

Compared to traditional house construction and also traditional modular house construction, we are somewhat more energy and environmentally friendly. This is especially true in areas such as:

- Transport – Instead of having concrete trucks, builders’ cars, glass and door companies, electricians, interior workers, roofers, and all others drive to the desired new house location, our installation vehicle only comes once and brings the finished house modules that require minimal installation on site. We also order materials in large quantities and at once. This means that one vehicle brings the windows for about 10 house projects, another vehicle about 5 sauna stoves, etc. This significantly reduces CO2 emissions. Additionally, ordering in large quantities results in a lower price for the end customer.

- Energy Usage – Since heating an underground house requires about 30% less energy than a traditional house, both the homeowner and the environment benefit. In terms of energy usage, it is also more economical to produce houses, cellars, and saunas in one location and in a controlled environment, and then transport and install them at the destination. Geothermal energy keeps the underground modules cool in summer and warmer in winter. Additionally, the indoor climate of the house is not significantly affected by outside storms and winds. The concrete infrastructure of the house and sauna stores the heat inside, keeping them warm for a long time after heating. Revonia cellars also work entirely without electricity. The energy savings of large cellars compared to equally sized refrigerators are incomparable.

- 100% renewable energy – In our production, we use only renewable energy, thereby reducing our CO₂ footprint and supporting a sustainable living environment.

- Land Use and Impact on Surrounding Environment – Most of our underground solutions are unnoticeable after installation. The most popular choice is to place windows and entrances on one side. This means that from three sides, the building appears to be just a mound of grass. The roof of the building can be planted with grass and plants or used as a terrace, sledding hill, solar energy park, parking space, and much more. The impact on the surrounding environment is minimal. Not much space is needed for installation and there is no need to remove surrounding trees. Later, the house is so well hidden in nature that you can often see wildlife in front of the house, not realizing that a large family home is hidden under the grass mound.

- Materials and Construction Resources – Concrete is not inherently the most environmentally friendly material. Neither is PUR foam. However, their footprint is reduced by the fact that a concrete module can be effectively used for about 100 years, averaging 2-3 times longer than an average wooden modular house. During this time, there is no need to replace the roof, wall materials, foundation, and much more that wears out in a traditional house. The long lifespan and minimal maintenance needs make the concrete modular house a quite resource-efficient solution for the future. In production, labor and materials are optimally distributed, meaning that material waste is minimal. Using standard solutions helps us keep costs down and ensures a constant stock availability.

- Interiors and Innovative Design – In the interiors, we create the climate with lime plaster, which is environmentally friendly and easily recyclable. Additionally, the modules have natural ventilation or, if desired, forced ventilation. Innovative modern construction techniques ensure quality and traditional vaulted ceilings ensure durability. Tried and tested solutions – in a new guise.

- Waste Management – When a traditional wooden house wears out, it is demolished and either used as fuel or ends up in a landfill. Additionally, demolishing a traditional house generates a lot of waste such as insulation materials, metal and plastic parts, and much more. These need to be sorted and recycled. With a concrete house, however, after being used as living space, it can be reused by future generations as a cellar, sauna, garage, or other storage space. Even in demolition, the concrete modules can be separated and reused if desired. In terms of reuse, Revonia houses mainly consist of concrete, steel reinforcement, PUR foam, and then other materials – electrical wires, ventilation pipes, etc. Separating and later sorting the materials is quite simple.

- Durability – As mentioned earlier, the expected lifespan of an underground concrete house is about 100 years. After that, it can still be used as a cellar, sauna, storage room, or something else. It is also worth considering what this house might look like in the future. It will most likely outlast the current owner and be used by future generations. Just as cellars built by grandparents are still in use today.

ALL YOUR TECHNICAL NEEDS ARE COVERED

Using only four modules you can construct vaulted structures from 4.5 m2 up to hundreds of square meters. Read more on our technology page.